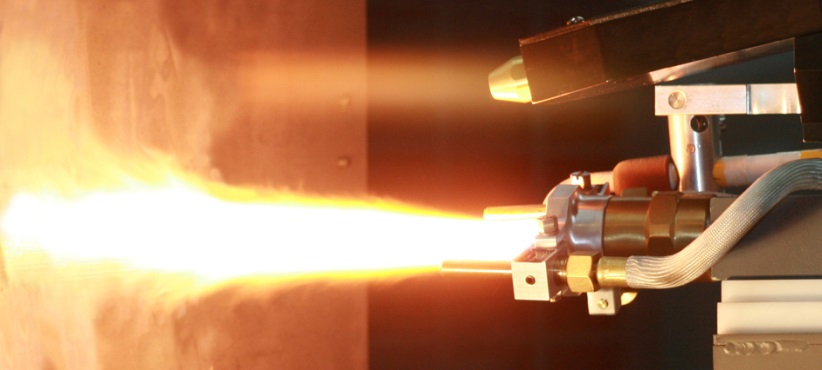

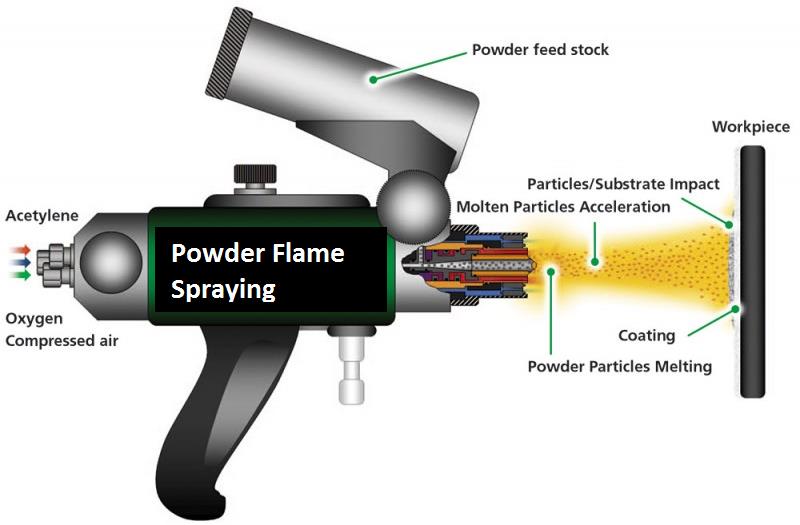

Flame spray coating is a thermal spray coating process that produces high quality surface coatings using heat, from the combustion of a fuel gas with oxygen, to melt a spray coating material which is propelled onto a substrate. Flame spraying offers a cost effective alternative for applying metallic and ceramic coatings in a less demanding environment. The process relies on the chemical reaction between oxygen and a fuel of combustion to produce a heat source. This heat source creates a gas stream with a temperature that excess over 3,000°C with balanced ratio conditions oxygen/acetylene. The feed stock powder material to be sprayed is fed into the flame in the form of a powder to melt and the thermal expansion of the combustion is then used to accelerate the particles onto the substrate.

The main advantage of this process is that a much wider range of materials (such as nickel or cobalt based self-fluxing alloys or ceramic materials) can be easily processed into powder form giving a larger choice of coatings.Typical coatings

- Self-fluxing alloys (fusing)

- Iron-based alloys

- Nickel-based alloys

- Chromium-based alloys

- Ceramics & Cermets

- Abradables

Main applications

- Wear resistance

- Corrosion protection

- Chemical resistance

- Erosion prevention

- Heat shielding

- Insulation

- Dimensional restoration

Combustion-Assisted Flame SpraYing (CAFSY)

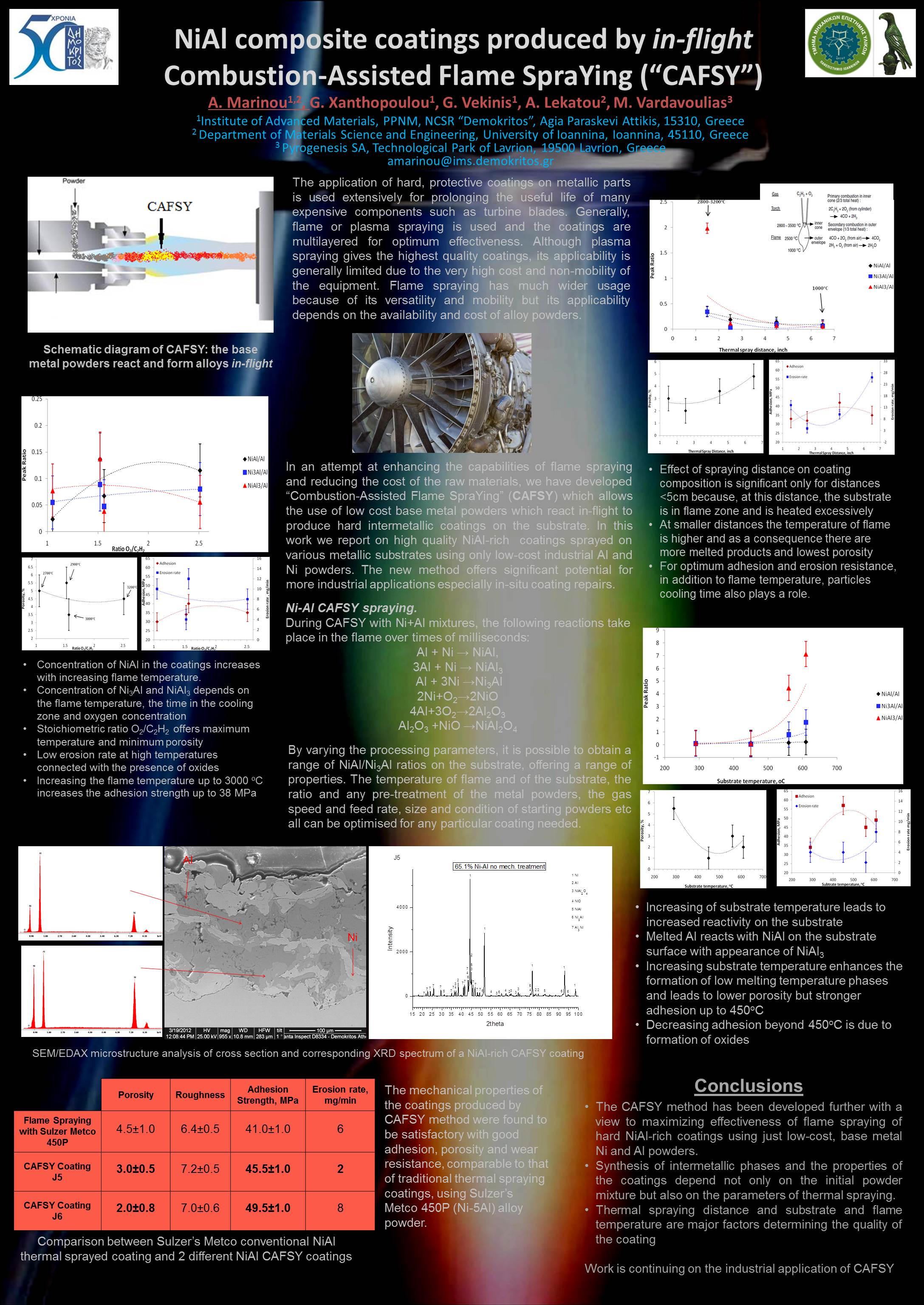

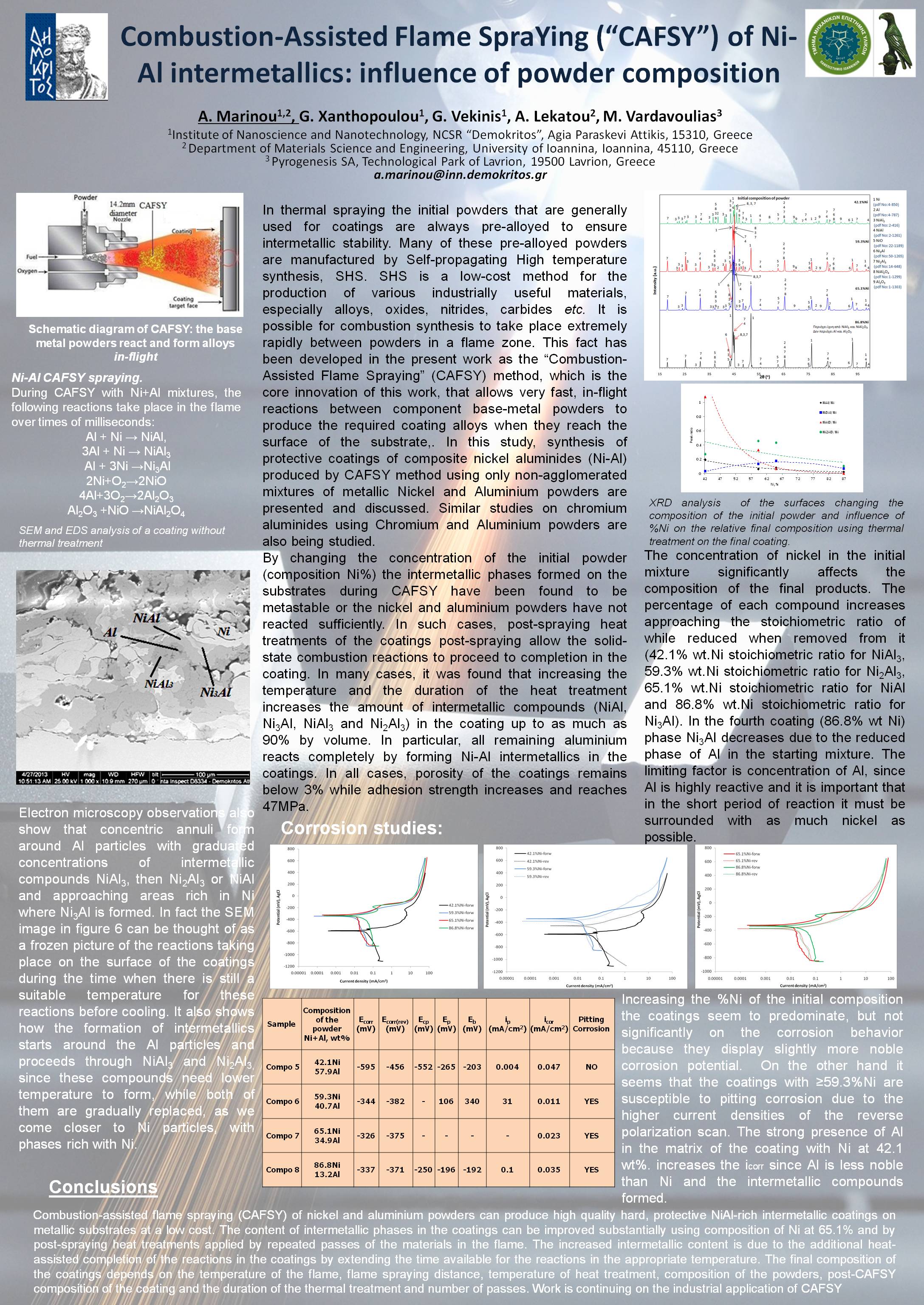

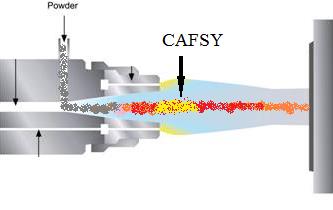

CAFSY is a new, cost-efficient and on-site-applicable thermal spraying process for depositing intermetallic overlay coatings or bond-coats for high temperature applications. It is characterised by synthesizing the desired intermetallic phases from base-metals in-flight during oxy-acetylene flame spraying. By adjusting the spraying conditions, excellent intermetallic-based coatings have been achieved on various substrates, including mild steel, stainless steel and aluminium alloys. The new method is called “Combustion-Assisted Flame SpraYing”, (“CAFSY”) and its viability has been demonstrated at a pre-industrial level for coating various metallic parts. The new method offers significant potential for more industrial applications especially in-situ coating repairs.

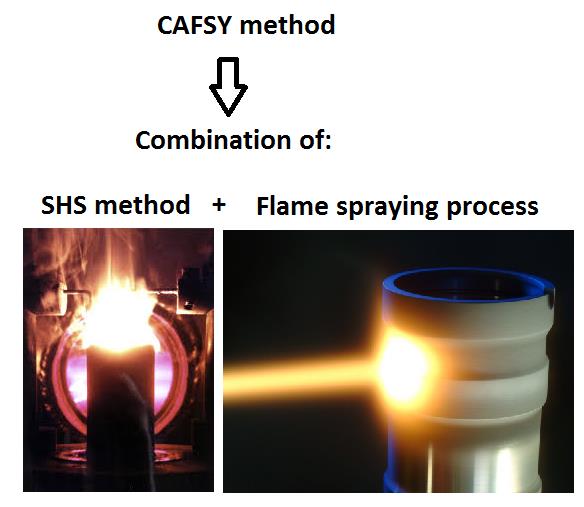

The synthesis of alloys using CAFSY combines two different methods, the Self-propagating High temperature Synthesis (SHS) [link] and Flame Spraying (FS). During CAFSY a mixture of base metal powders is introduced into the flame during convectional thermal spraying and self-ignites and reacts exothermically (above, left) during the flight stage producing in-situ intermetallic coatings on the substrate. The CAFSY method is a new approach to the synthesis of intermetallic coatings that has never been used before either in an industrial or research level. The exothermic reactions during flight increase the available energy thereby reducing the required reaction time between based metals (eg. Ni and Al), rapidly synthesising the intermetallic compounds (eg. NiAl and Ni3Al) (right). An additional important advantage is the significantly lower cost of producing hard coatings by this method, since, for example, Ni and Al powders are widely commercially available so there is no need to use the expensive pre-alloyed powders generally used for the thermal spraying.

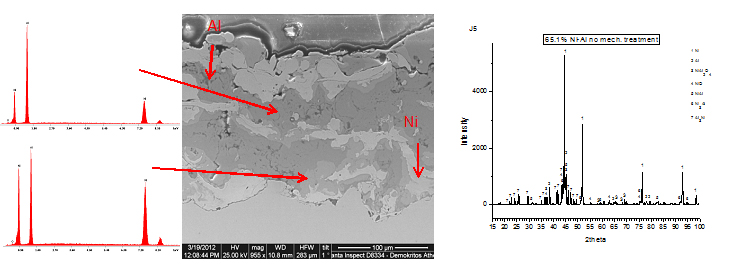

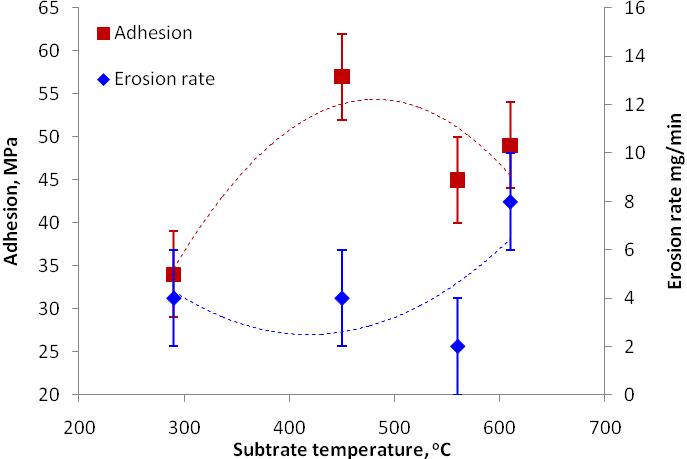

The Ni-Al-based coatings produced by CAFSY exhibit very high integrity with good adhesion, low porosity, high surface hardness and high erosion resistance (left and right) at a substantially lower cost than equivalent coatings using ready alloy powders, since they are made using only simple oxy-acetylene flame spraying.

For example, increasing substrate temperature leads to increasing combustion temperature on the substrate during continuing exothermic reactions. Melted Al reacts with NiAl on the substrate surface with the appearance

of NiAl3. Ni3Al, and NiAl3 which have low adiabatic temperatures and therefore need higher preheating temperatures of substrate for their reactions to initiate.

Increasing substrate temperature also enhances the formation of low melting temperature phases and leads to lower porosity but stronger adhesion up to 450oC. Decreasing adhesion beyond 450oC is due to formation of oxides

CAFSY has been developed to maximize effectiveness of the convectional flame spraying process for hard coatings and reduce its cost. The synthesis of intermetallic phases and the properties of the coating depend on the parameters of thermal spraying process and the thermal treatment of the produced coating.

- Hard, protective coatings for metals 2.Catalytic coatings on ceramic substrates